Companies are working with various solutions to find a way on how they can separate solid materials from liquid. Having a filter press is so important when time comes. On the other hand, what makes the entire process more difficult for the customers is the selection of such machine. It is critical that consumers have done their due diligence to make sure that they're making the right decision given the fact that there are many of them to choose from.

For customers, it is vital that they figured out what they need exactly. There are 2 different kinds of machines to be chosen from and both perform a slightly different job. The said systems could be manual or automatic, which pretty much work the same. Of course, the exceptions that it have is the fact that manual machines are manually operated and automatic machines can be automated so to speak.

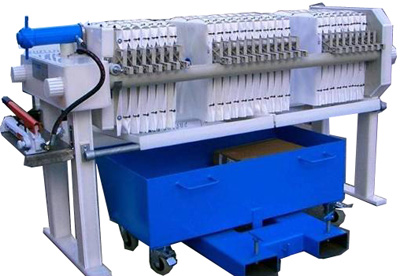

Both of the machine's frame and filtro prensa is also called as membrane filter plate. What this compose of are frames and plates that are alternating. In keeping the solids suspended so there's no setting throughout the process, a centrifuge pump is used too. And as the liquid is delivered in the machine, the solids collected on to the cloth suspended over the frames, which separate the chambers. Cake is what called to the frame that's soiled; when it reaches that point, the process is stopped and cleaned liquid is funnelled off through the collection pipe. The "cake" is then removed at the plate and will discharge the solids to the collection point.

Recessed filtro industrial machines use the same principle in removing solids from liquid. The plates in the system are around 2 to 4 feet across and have concave depression in middle, hence its name. The solution is then squeezed in the opening, which has cloth pulled across to it. Like before, the liquid goes through and solids remain, forming cakes. The cake on the other hand could not get more than 32 mm thick before it gets cleaned. What's more, the machine is going to take longer to change the cloth and might form uneven cake.

If you think that manufacturers of filter press are only capable of producing machines that separate solids and liquids, you're wrong as they are also manufacturing individual parts to run it smoothly. This allows consumers to buy the machine and other repair or replacement parts that are necessary to operate it. Parts similar to manifolds, piping, shifters and hydraulics might have to be replaced every now and then. Just before you finalize your mind in buying a filter press machine, make it a point that the manufacturer is producing other parts to be able to maintain the system so you won't have any issues in the long run. You can visit http://cnnpressroom.blogs.cnn.com/category/press-releases-do-not-select-this-just-used-to-filter/cnn-digital-press-releases/ for more ideas about the topic.